Manufacturing testing, re-engineered for production

A platform-independent automated test engine designed for PCBA and final acceptance testing in real factory environments. Replace heavy LabVIEW-style stacks with a lightweight, structured, reusable runner: faster script development, consistent operator execution, and controlled maintenance tools.

Script-driven execution, built for technicians

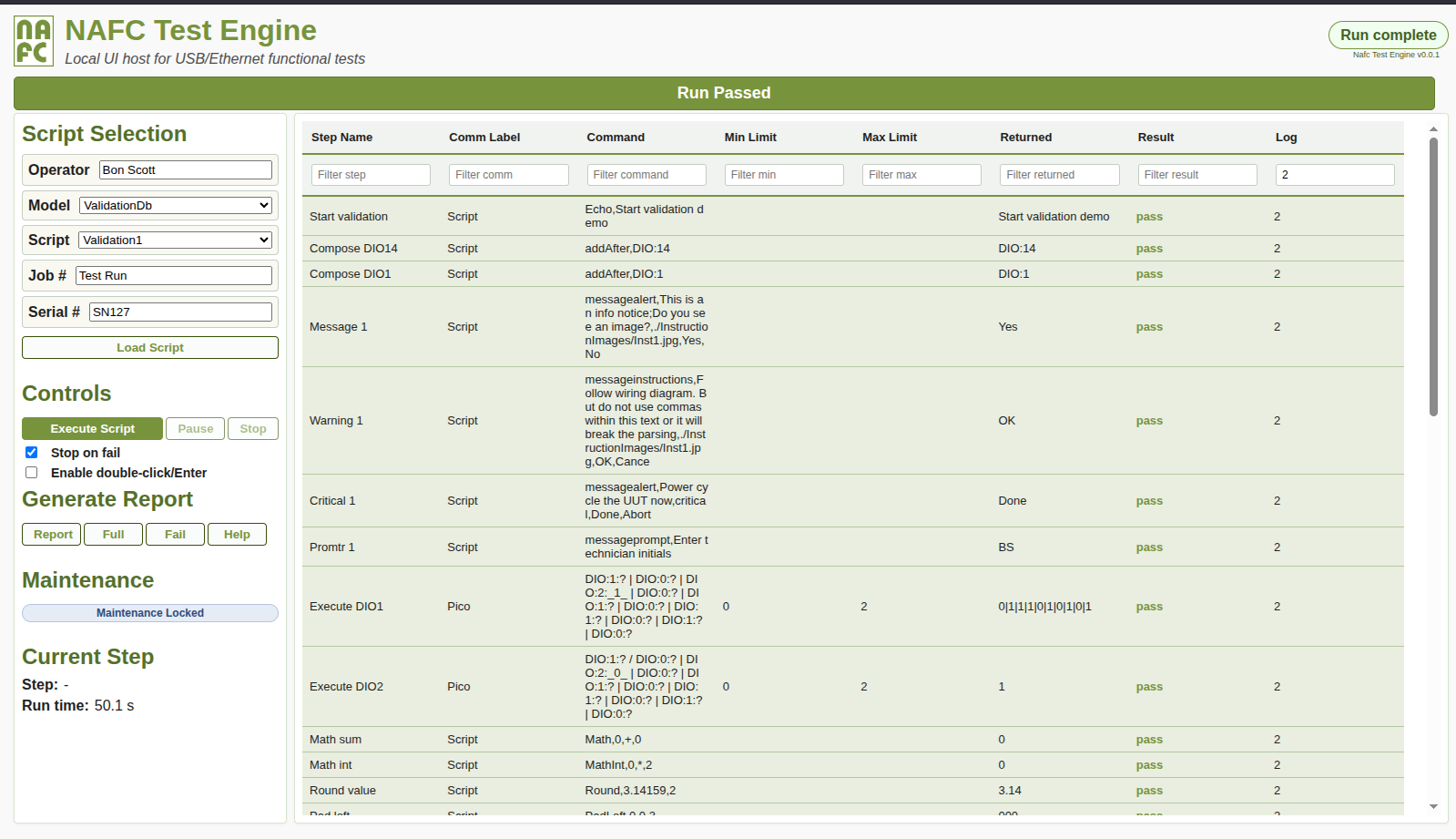

Tests are defined as a structured step table (Step Name, Comm Label, Command, Min/Max, Returned, Result, Log). The engine dispatches steps to the correct adapter, captures Returned values, evaluates limits, and generates filtered reports (Log / Full / Fail).

Operator-focused UI

Clear pass/fail state, prompts/alerts/instructions with images, maintenance lock for controlled edits, and reports for traceability.

Core capabilities

Designed around production constraints: repeatability, controlled change, low false-fail risk, and maintainability.

Device adapters

Serial/COM/USB, Ethernet GET/POST + raw payload, and Windows DLL integration for vendor APIs.

- Auto-find device profiles by command/expected response

- Host/port stored in profile for concise commands

- Vendor drivers via configured DLL entry point + calling convention

Scriptable logic (no programming)

Table-driven execution with swaps, cascades, branching, jumps, delays, and inline reporting.

<Step Name>swaps Returned values[Step Name]swaps result state for flow control- Chain commands with

|or/; reuse_index_outputs

Manufacturing-ready logging

Log filtering, stop-on-fail, troubleshooting mode, and report generation.

- Log/Full/Fail report views

- Hidden background steps (Log 0/1) with failure visibility

- Post-EndScript actions for autosave/print/custom logging

Execution workflow

Simple operator flow, predictable backend dispatch.

Operator flow

- Select Model/Script, enter Job + Serial, then Run.

- Engine executes each step: send → Returned → limits → Result.

- Dialogs appear when required (instructions/photos, prompts, confirmations).

- Stop-on-fail halts on first failing limit; single-step available for troubleshooting.

Backend dispatch (summary)

- Comm Label resolves to adapter (Script/Serial/Ethernet/DLL).

- Cascaded commands execute in order;

_index_reuses prior results. - Runs logged + reports generated by filter (Log/Full/Fail).

- Maintenance lock controls editing access on the factory floor.

Integration notes

Practical connectivity patterns for real devices.

USB / Serial (COM)

- Works directly with virtual COM ports exposed by vendor drivers.

- Auto-find profiles bind the correct device using ID/expect matching.

- Use send-only commands via a “fire” style when no response is required.

Ethernet

- GET/POST and raw payload styles supported.

- Store host/port in the profile; keep commands concise in scripts.

- Prefer IPv4 endpoints for consistent resolution.

Windows DLL adapters

- Bridge to vendor APIs without writing custom code.

- Configure DLL path, function name, calling convention, return type.

- Supports both virtual COM and vendor-supplied DLL APIs.

Fixtures + UI

Fixtures are part of a complete system: robust harnessing, clear operator indicators, and scripts that include wiring/setup guidance. See the dedicated fixture page for the design approach.

Contact / Demo

Ready to change how you perform final verification and acceptance testing?

What we’ll cover in a demo

- Script table model + comm label device profiles

- Operator dialogs with images + maintenance lock

- Stop-on-fail + single-step troubleshooting

- Report generation (Log/Full/Fail)

- Fixture integration: wiring instructions + prompts