Fixture design that reduces false fails and maintenance time

Fixtures are part of the test system. The NAFC approach focuses on short, labeled, strain-relieved internal harnessing and purpose-built internal PCBs to replace point-to-point wiring — improving robustness, repeatability, and serviceability across stations.

Observed pain points (legacy fixtures)

- Dense “rat’s nest” wiring: hard to service, fragile connections, noisy signals.

- Limited strain relief and labeling → slow rework/changeovers.

- Awkward board access; setup depends on tribal knowledge.

- Lower repeatability between stations and higher false-fail risk.

Advantages (current NAFC fixture)

- Short, labeled, strain-relieved harnessing reduces noise pickup and failures.

- Purpose-built internal PCBs replace point-to-point wiring for repeatability.

- Clear operator indicators (status LEDs / progress bar) support fast execution.

- Accessible board area for probing; connectors and boards are easy to replace.

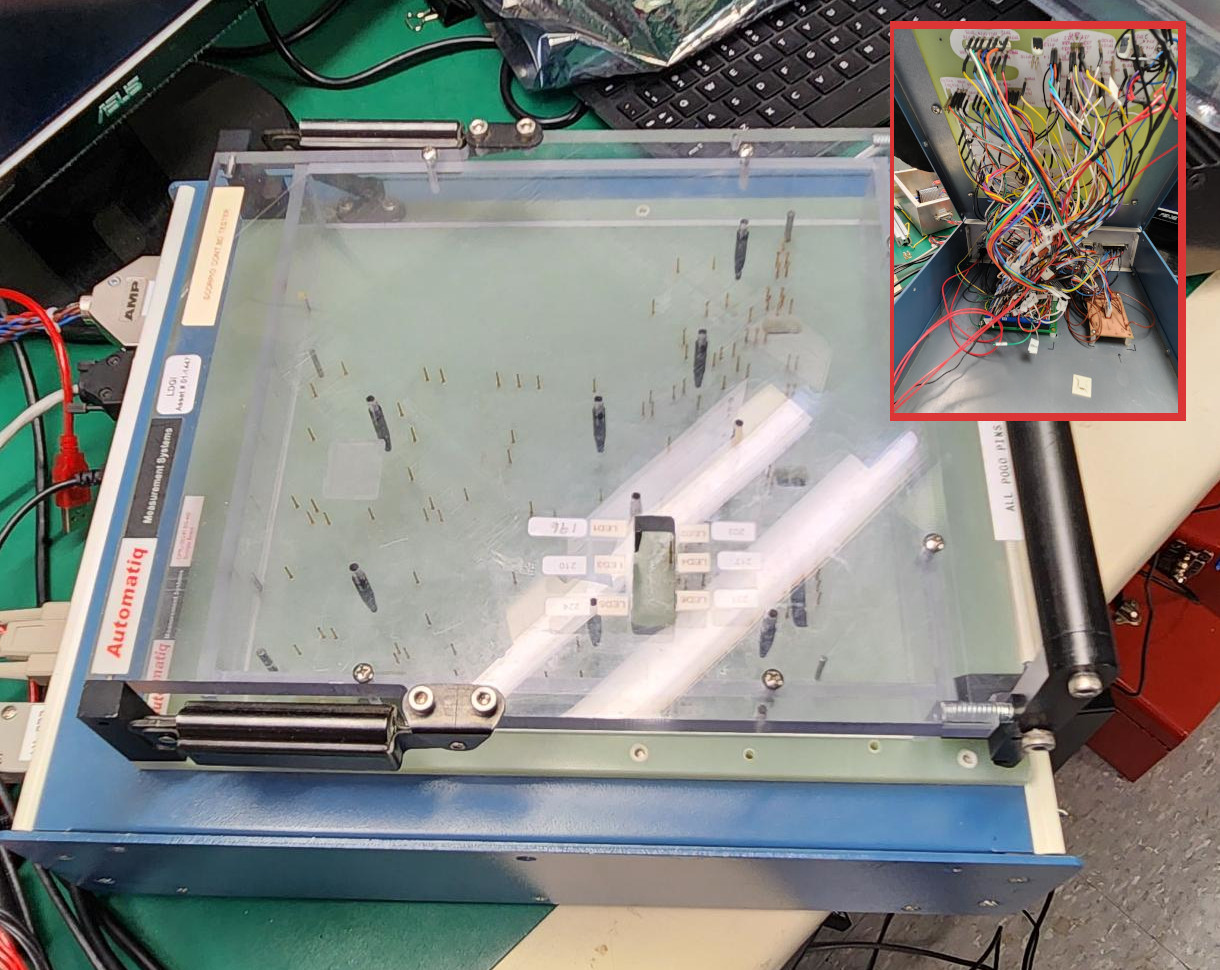

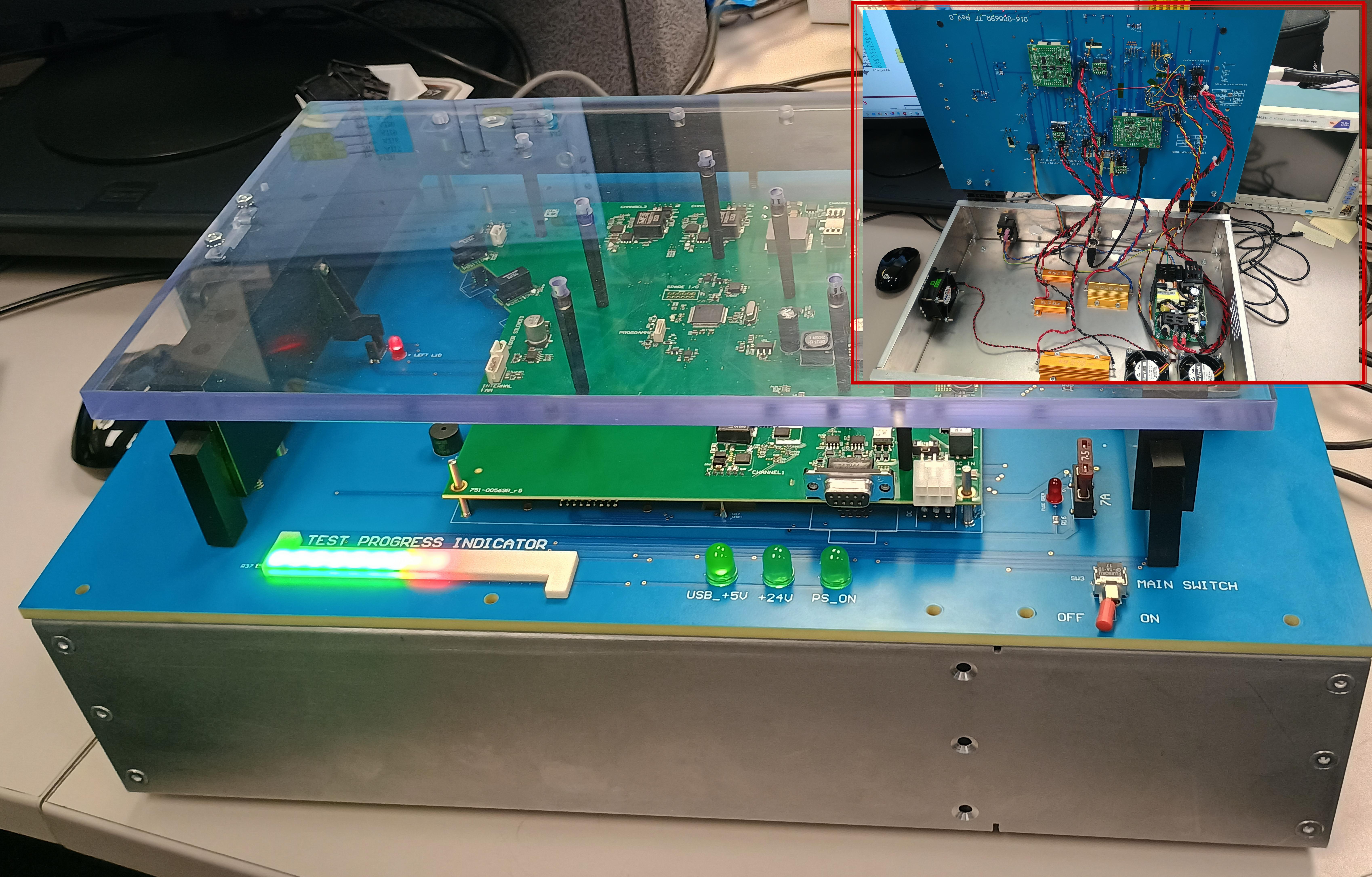

Before / After

Visual comparison from the current NAFC Test Engine materials.

Legacy fixture: wire-heavy

Higher noise susceptibility, harder servicing, slower changeovers, and higher variability between stations.

NAFC fixture: robust + serviceable

Short harnessing, internal PCBs, and operator indicators improve repeatability and maintenance speed.

How fixtures fit into the Test Engine

Use the engine’s operator dialogs and logging controls to make fixtures easy to use and audit.

Wiring / setup guidance

Use instruction dialogs with images for fixture connections, jumpers, and checkpoints.

- Instruction dialogs for wiring photos

- Reduce tribal knowledge

- Improve repeatability across stations

Controlled prompts

Capture technician initials, workcell, and confirmation inputs during run.

- Traceability for regulated environments

- Clean operator experience

- Consistent data capture

Clean logging strategy

Keep operator-visible steps at Log=2; background setup/control at Log=0/1.

- Operator sees what matters

- Failures still surface hidden steps

- Reports stay concise

Next steps

If you want, we can tailor a fixture + script strategy for your UUT and your production constraints.